Introduction

Have you ever wondered what makes a fish feed pellet float? Or why some pellets sink to the bottom and stay there without falling apart? It’s not magic. It’s a specific set of technologies and machines. They are designed for the unique needs of fish farming.

The main goal of modern fish feed technology is to create a nutritious and easy-to-digest pellet. The pellet also needs to be stable in water. This ensures you get all the valuable food to your fish with very little waste. This guide will break down the key technologies. We will also look at the essential technology and machine used in making fish feed. We will explain what each one does and why it’s important.

The Core Technology: Extrusion vs. Pelleting

At the heart of making fish feed are two main technologies. The one you choose determines if your feed floats or sinks.

Extrusion Technology (For Floating & Slow-Sinking Feed)

What it is:

This is a process that uses high temperature, high moisture, and high pressure to both cook and form the feed. Think of an extruder machine as a high-pressure cooker that also shapes the food at the same time.

The Science Explained Simply:

This intense cooking process causes the starches in the feed ingredients to gelatinize and expand. This traps tiny pockets of air inside the pellet. This trapped air is what makes the pellet light and allows it to float on the water. This process also helps to sterilize the feed, making it safer for your fish.

Best for:

Most surface-feeding fish like Tilapia, many types of Catfish, and other similar species.

Pelleting Technology (For Sinking Feed)

What it is:

This is a process that uses high pressure and steam (from a step called conditioning) to compress a feed mixture into dense pellets. It does not involve the same high level of cooking or expansion that happens in an extruder.

The Science Explained Simply:

This process relies on pure compression and binders in the feed. This creates a heavy, dense pellet that sinks quickly and holds together in the water.

Best for:

Bottom-feeding species like shrimp and some other types of catfish or carp.

The Machines of a Fish Feed Production Line (A Step-by-Step Look)

A fish feed production line uses several machines in a specific order to create the final product.

The Grinder (Hammer Mill or Pulverizer):

This is where the process begins. The grinder takes all the raw ingredients, like corn, soybean meal, and wheat. It grinds them into a fine, consistent powder. A fine grind is very important for good fish digestion. It also helps the other machines in the process work well.

The Mixer:

After grinding, the different powders are blended with micro-ingredients. These include vitamins, minerals, and binders. A good mixer ensures that every single pellet will have the same, identical nutritional value.

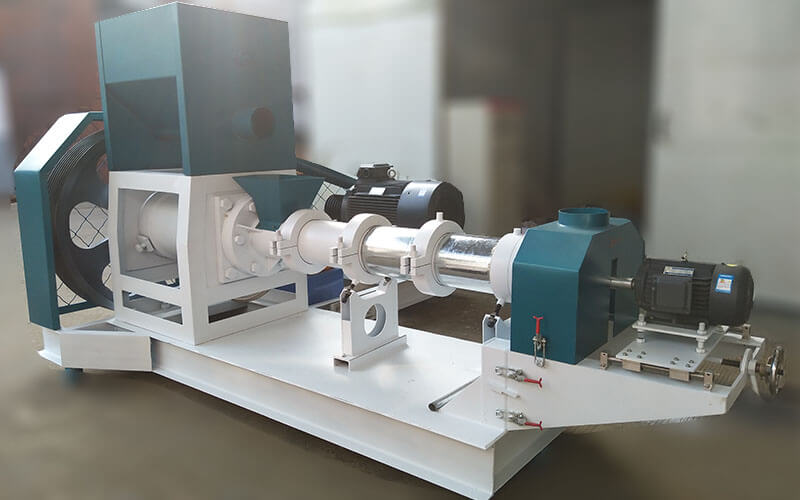

The Extruder OR The Pellet Mill (The Heart of the Line):

This is the main technology and machine used in making fish feed. A fish farmer chooses an extruder if they want to make floating feed. They choose a pellet mill if they want to make sinking feed. This is the most important machine choice in the line.

The Dryer:

Freshly made pellets, especially extruded floating pellets, are hot and moist. A dryer uses circulating hot air to reduce the moisture content to a safe level, which is usually below 10%. This is a critical step for making feed that can be stored without spoiling.

The Coater:

After the pellets are dried and cooled, a machine called a coater can spray them with oils or fats. This is often done last. This is because the high temperatures inside an extruder can damage these sensitive fats and oils. This step adds energy to the feed. It also makes the feed more attractive to the fish.

The Cooler & Packer:

After coating, the cooler brings the pellets down to room temperature before they are put in bags. The packer then weighs and bags the finished product. This makes it ready for storage.

Key Technologies and Considerations for Quality Fish Feed

Beyond the main technology and machine used in making fish feed, some key technology concepts are important for making good fish feed.

Particle Size Technology (Grinding Fineness):

Choosing the right screen (or mesh) in your grinder is a key choice of technology and machine in making fish feed. It allows you to match the final feed particle size to the mouth size of your fish. This is especially important for very small fry.

Steam Conditioning Technology:

Conditioning is the process of adding steam to the feed mix before pelleting or extruding. This is an important technology. It’s not just about adding water. The controlled heat and moisture improve how durable the pellet is in water. It also makes starches easier for fish to digest.

Post-Pelleting Liquid Coating Technology:

This is a key technology for making modern fish feed. It allows for high-energy fats and heat-sensitive vitamins to be added to the outside of the pellet. This happens after the high-temperature cooking process is finished, which protects these valuable nutrients.

FAQ

What is the main machine that makes fish feed float?

A: The main machine is the fish feed extruder. It works like a high-pressure cooker that cooks the feed mixture. This causes the feed to expand and trap air inside. This trapped air is what makes the finished pellets light and allows them to float.

What’s the biggest difference between a feed extruder and a feed pellet mill?

A: The biggest difference is how they work and what they produce. An extruder cooks and expands the feed to make light, floating pellets. A feed pellet mill compresses the feed to make dense, sinking pellets. Extruders are generally more complex and more expensive than pellet mills.

Why is grinding the ingredients so important for making fish feed?

A: Fish, especially young ones, have simple digestive systems. A fine grind (which means small particle size) makes the nutrients in the feed much easier for them to absorb. It also helps create a smoother, more uniform mixture. This leads to stronger, more water-stable pellets.

Why is fish oil often added after the pellets are made?

A: The high temperatures that are used inside a feed extruder can damage the valuable and sensitive Omega-3 fatty acids found in fish oil. By “coating” or spraying the oil onto the finished, cooled pellets, these important nutrients are protected from the heat of the cooking process.

What is the most critical technology for making good quality fish feed?

A: While every step is important, many experts would say the extrusion or pelleting technology itself is the most critical. This is because it determines the final physical form of the feed (whether it floats or sinks). It also has a huge impact on its digestibility and how stable it is in water. These are all vital for successful fish farming.

Conclusion

Making modern fish feed is made using a combination of key technologies. The main choice is between extrusion (for floating feed) and pelleting (for sinking feed). This technology in making fish feed is carried out by a series of specialized machines.

These include a grinder, a mixer, an extruder or pellet mill, and a dryer. Understanding this technology and these machines helps fish farmers produce higher quality, more effective feed for their specific needs. This leads to healthier fish and a more profitable farm.