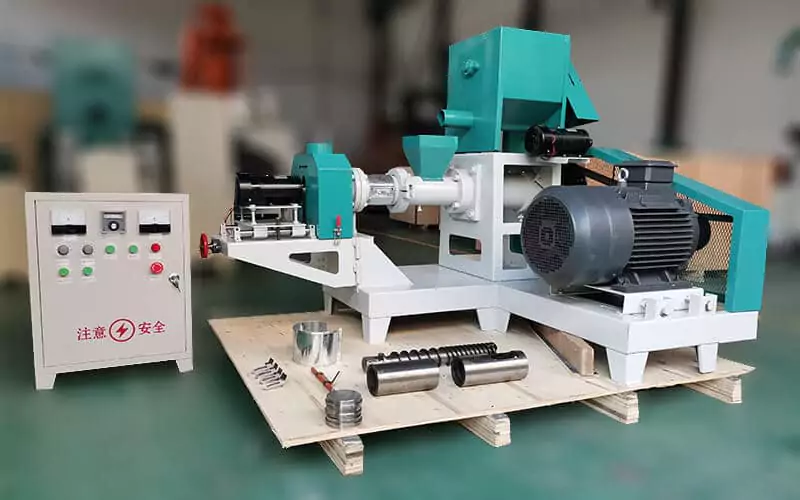

Successful Export of Floating Fish Feed Pellet Extruder to Vietnam

In October 2018, we achieved a breakthrough by exporting a floating fish feed pellet extruder machine to Bạc Liêu Province of Vietnam. This machine production capacity is 50-60kg/h. It can increase tilapia yields by 19% for local cooperatives, earning certification from Vietnam’s Ministry of Agriculture . The floating aquafeed equipment is now recommended for Mekong Delta government subsidy programs.

Technical Adaptations

- Voltage tolerance 380-450V for unstable rural grids

- 304 stainless steel screws resisting Mekong salinity

- Bilingual interface

Why Vietnam’s Fish Farms Need Floating Feed Machines

Floating fish feed pellet extruder machine is now essential for Vietnam fish farms. It can help farmers to raise much healthier fish, cut cost, and meet rising demand. It is the key reasons why more Mekong Delta farms adopted the fish feed making machine. Whether you run a family pond or large fish farming, the machine can offer you a proven path to success.

Bigger Farms Need Better Extruder

As fish farms grow across Vietnam’s Mekong Delta, old feeding methods no longer work. Modern floating fish feed pellet extruder machine will solve this by making 50–500 kg of feed hourly. The production capacity is enough for 15 ponds. Small farms or large farms can save time and money with using this machine. Farmers in Can Tho saw the fish grow faster after switching to floating feed.

Enhanced Fish Health and Growth

The final floating feed can float on water for about more than 12 hours. It makes fish to eat over 90% of food vs. 60% sinking feed pellets. This means less wasted feed and cleaner water for healthier fish. Faster growth (20–28% for tilapia, per 2023 Vietnam Aquaculture Report). A steam-cooking process makes feed easier to digest with rich proteins and vitamins fish need.

Cutting Costs, Boosting Profits

Fish farmers in Vietnam can use local ingredients like corn, wheat, and rice to make fish feed. It can reduce 35% cost on raw materials and farmers get more profits. They can alos change the fish feed recipes freely for young and adult fish.

Understanding Fish Feed Machine Prices in Vietnam

the price of floating fish feed pellet extruder machine in Vietnam can range from USD2000 to USD60,000. But local machines often cost less, while imported machine price may be higher but it can last longer time with better technology and quality. It depends on the machine size, features, and quality. Smart buyers always check service support and import taxes before deciding. Let’s explore what shapes these prices:

Raw Material Costs:

The materials of the machine also affect the machine price like steel, rubber, and electrical parts. For example, Vietnam’s steel costs rose 15% in 2023. The machine sellers must charge more to keep their profits when the material price goes higher. The local sellers now use Vietnamese-standard steel to control the cost better.

Tech Upgrades Change Costs

New features make the fish feed pellet extruder price in Vietnam increased at first like automatic temperature controls . However, these advanced features can help farmers to save money and time in future. A 2024 Mekong Delta study showed farms who used the machine with advanced features cutting energy cost .

Labor Costs:

Workers and labors cost go higher and higher along with Vietnam growing economy. Factory production cost increased 8% only last year. Some manufacturers now train workers in mechatronics to boost productivity and offset wage hikes.

Service Adds Value

Machines with free maintenance contracts or 3-year warranties often cost 10-15% more. But this pays off long-term. Fish farmer in Đồng Tháp Province shared: “Our machine broke after 18 months. The free repairing saved us $1,200, it is worth the extra initial cost.”

Hidden Operating Costs

Cheaper fish feed pellet extruder in Vietnam might need more power or frequent part replacements. Energy-efficient models with Vietnam’s 5-star rating can cut electricity energy. You should always compare:

- Ease of cleaning and maintenance

- Power needs per kilogram of feed

- Local spare parts availability

Big Factories Offer Deals

Large manufacturers can offer better price, because they can produce more than 100 machines per month. They buy the materials in bulk. However, smaller Vietnamese workshops now group orders through farming cooperatives to get volume discounts too.