Introduction of fish feed pellet extruder in ghana

For fish farmers across Ghana, especially those raising catfish and tilapia, the biggest challenge is often the high cost of quality floating feed. It can feel like your profits are being eaten up before your fish even take a bite. A fish feed pellet extruder machine is the specific tool designed to solve this problem. It allows you to produce your own high-quality, buoyant feed using local ingredients, putting you in control of your costs and your farm’s success.

This guide is written for you, the Ghanaian fish farmer. We’ll explain what an extruder is, why it’s so important for your fish, where to find suppliers, and the critical questions to ask before you invest.

What is a Fish Feed Extruder? (And Why It’s the Right Machine for Tilapia & Catfish)

Think of an extruder as a high-pressure cooker that also shapes the food. It takes your mixed feed ingredients, cooks them with intense heat and pressure, and then forms them into pellets that puff up and float.

The most important feature of this machine is that it makes feed float. Since popular fish in Ghana like tilapia and catfish are surface feeders, floating feed allows you to see them eat. This drastically reduces waste and helps keep your pond water clean. A standard pellet mill cannot do this; it only makes sinking feed.

The Real Advantages for Your Ghanaian Fish Farm

Investing in your own extruder offers clear, practical advantages for your farm in Ghana.

Take Control of High Feed Costs.

You can create high-quality feed using locally available and often cheaper fish feed ingredients. These include common Ghanaian crops like maize, soybean meal, groundnut cake, and fish meal from local sources. This is much cheaper than relying on expensive commercial feeds.

Improve Your Fish Growth and Health.

The cooking process inside an extruder, known as starch gelatinization, makes the feed much easier for fish to digest. This leads to better nutrient absorption. Better absorption means a better Feed Conversion Ratio (FCR), which is key to faster growth.

Ensure a Consistent, High-Quality Feed Supply.

“You are no longer dependent on market availability or the variable quality of different feed brands. You control the recipe and the freshness of the feed every single day.”

Create a New Business Opportunity.

Once you are making enough feed for your own farm, you have a chance to sell your excess, high-quality floating feed. You can supply the growing number of other fish farmers in your community.

Finding Suppliers in Ghana: Where to Look

Finding a good, reliable supplier is a key step.

- Major Commercial Hubs: Accra and Kumasi. These cities are the primary centers for agricultural and industrial machinery importers and dealers in Ghana.

- Look for Specialized Aquaculture or Agricultural Dealers. It is best to seek out suppliers who have specific experience with fish feed equipment, not just general-purpose sellers. They will understand your needs better.

- Use Online Platforms & Farmer Networks. You can search on popular Ghanaian platforms like Jiji Ghana and Tonaton. Also, it is a very good idea to ask for trusted supplier recommendations in Ghanaian aquaculture groups on Facebook and WhatsApp.

- Local Fabricators vs. Imported Machines. There are local workshops that can build machines. These might be cheaper and easier to repair. However, an imported machine (often from China) usually offers more precision and better technology for making high-quality floating feed.

A Buyer’s Checklist: What to Ask Before You Invest in Ghana

Think carefully before you buy. Ask these important questions:

What is Your Real Power Situation?

“This is the first and most important question for a farmer in Ghana. Is your grid power supply (dumsor) reliable enough to run a powerful electric motor without interruptions? If not, a diesel engine model is a necessary investment for a serious business.”

What is Your Required Capacity (in kg per hour)?

Match the machine’s output to the size of your ponds and your daily feeding needs.

Check the Screw and Barrel Quality.

“These are the heart of the extruder and do all the hard work. They must be made from high-quality, wear-resistant alloy steel to last a long time. Ask the supplier about the material they use.”

Ask for a Demonstration.

“Before you pay, ask the supplier in Accra or Kumasi: ‘Can you show me the machine working? Can you run some maize and soy through it to see the pellets float?’ A good supplier should be able to demonstrate their machine.”

What About Spare Parts and After-Sales Support?

“A breakdown can be a disaster for your feeding schedule. Ask the supplier directly: ‘Do you have spare parts like screws and dies in stock here in Ghana? If my machine has a problem, can you provide technical help?'”

Cost & Financing Considerations in Ghana

You need a smart money plan to buy a fish feed pellet extruder machine in Ghana. Price changes based on machine size, brand trust, and special features. Let’s break down costs for both farm owners and big feed factory buyers.

Machine Price Ranges

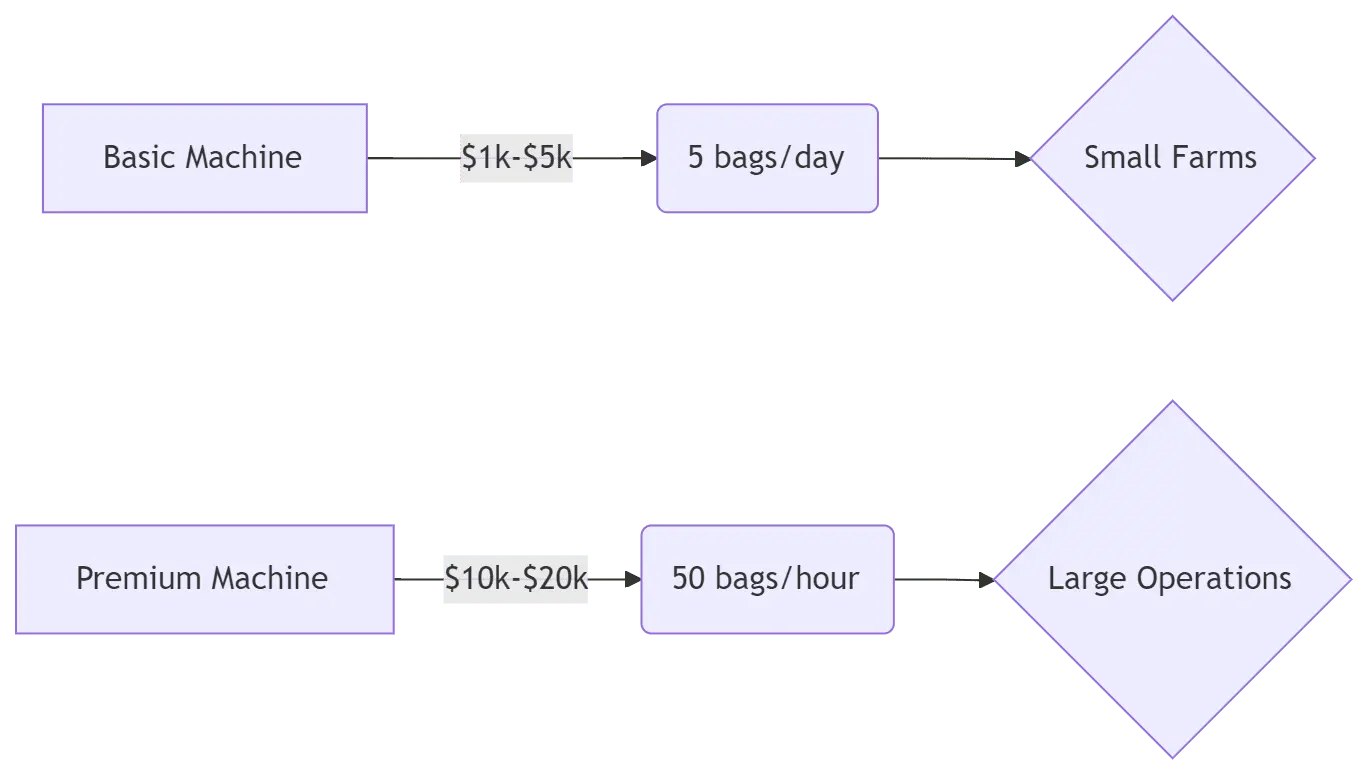

Small Farm Models ($1,000-$5,000)

These cost-friendly floating feed machine works best for new fish farmers. They make 50-200kg per hour which is perfect for 2-3 ponds. Because cheaper, they need more workers to operate and extra cost for repairs.

Commercial-Grade Models ($10,000-$20,000)

Big fish farms or big feed factory use these heavy-duty fish feed pellet machines. They can make more feed than 500-1000kg per hour. It has automatic systems that need fewer workers. Prices include stainless steel parts that last 5+ years in Ghana’s humid climate.

What Changes the Final Price?

Brand Value Matters

machines made in Ghana from Takoradi Engineering Works can save upfront cash but also may need more fixes.

Smart Features Add Cost

automatic fish feed pellet extruder machine need less labor, but may add extra $3,000-5,000 to the machine price. Equipment with German-made motors can last longer in power-less areas. also, you should always ask about spare parts.

Durability Costs Less Over Time

304 stainless steel machines cost 30% more upfront but survive Ghana’s rainy seasons better. Cheaper carbon steel models rust faster near coastal areas. Farmers in Sekondi-Takoradi report stainless models last 3x longer.

Hidden Costs to Watch

Warranty Tricks

Some suppliers offer 5 years warranty, but except for key spare parts like the fish feed pellet extruder machine screws and dies. Make a good contract, sometimes good contracts can cover at least 80% of the parts for 2+ years.

Service Contracts That Pay Off

Monthly maintenance plans ($50-$200) prevent breakdowns during peak seasons. Fisherman’s Co-op in Accra offers free training with their service packages – a smart choice for new users.

Money-Saving Tips

- you can cut prices by 10-15% through group buying the fish feed pellet extruder machine together with other farmers.

- Look for demo models, they generally cost 20% less with full warranty.

- Check Ghana Bank agri-loans with 12% interest rates.

Local successful story:

Akuapem Hills Fish Farming bought a fish feed pellet extruder machine with $15,000 in 2022. They recovered the cost in 14 months through proper care and group buying raw materials. What is their secrect? the answer is they buy spare parts like screws and dies in bulk, and monthly grease checks.

Price Comparition Chart

Conclusion

For Ghanaian fish farmers, the fish feed extruder machine is the key to producing the high-quality floating feed that is essential for species like tilapia and catfish. While it is a significant investment, it is a powerful tool for controlling costs, improving fish health, and building a more profitable and self-sufficient aquaculture business in Ghana.

FAQ About Fish Feed Pellet Extruder in Ghana

1. What is the main difference between a feed extruder and a regular pellet mill?

A: An extruder cooks and expands the feed under high pressure to make it light and float on water. A regular pellet mill simply compresses the feed to make a dense, sinking pellet. For floating catfish and tilapia feed, you must use an extruder.

2. Is a diesel or electric extruder better for a farm in Ghana?

A: A diesel engine model is often a safer and more reliable choice for many farmers in Ghana. This is due to the challenges with the public power supply (dumsor). If you are located in an area with a very stable power grid, an electric model can be cheaper to run.

3. Do I need a dryer with my fish feed extruder?

A: Yes, absolutely. The extrusion process adds a lot of moisture to the pellets. You must use a dryer to reduce this moisture to a safe level (usually below 10%). If you do not dry the pellets properly, they will quickly grow mold and spoil.

4. What are some good, low-cost ingredients for making floating fish feed in Ghana?

A: The best ingredients are often local agricultural by-products. Maize is a great energy source. For protein, soybean meal and groundnut cake are excellent. Locally sourced fish meal can also be used to boost protein and attractability.

5. Is it better to buy a locally made or an imported extruder in Ghana?

A: This is a difficult question. Imported machines are specifically designed with the technology to make high-quality floating feed. Locally fabricated machines might be cheaper, but they are often simple pellet mills that cannot make true floating feed. For making floating fish feed, an imported extruder is usually the better and more reliable choice.