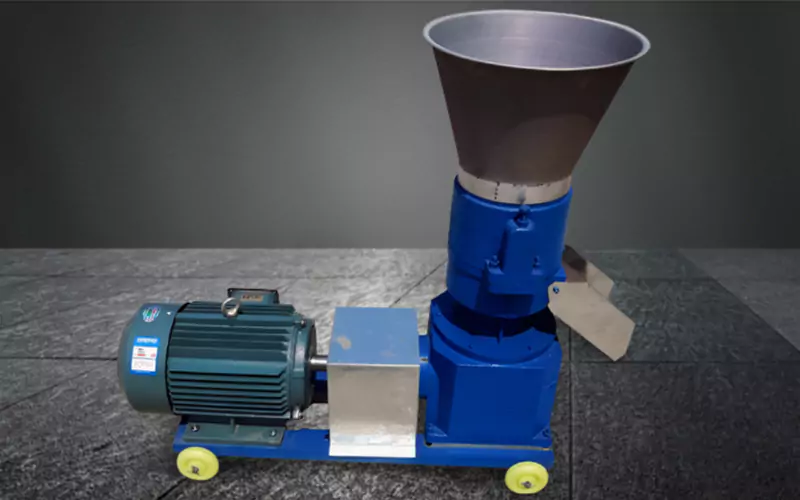

Feed Pellet Machine project: Colombia Export Breakthrough

In 2019, we successfully exported our VTKLP-210 feed pellet machine to Colombia. With a production capacity of 500kg/h, it meets the daily feed needs of mid-sized cattle farms. We make our machine with SUS304 stainless steel, the machine performs reliably in Colombia’s humid and mountainous environments.

The key lies in its integrated heating chamber. it can produce durable 12mm pellets better for cattle nutrition by processing local corn and coffee husks, . Farmers show a 20% increase in cattle weight gain and monthly feed savings of over USD 1,200. According to a farmer in Medellín of Colombia, “It’s the best investment I’ve made, the animal feed pellet machine has consistent quality, low cost, fast support.”

Production Capacity: Meeting Specific Needs

Our feed pellet machine fit any farms in Colombia like well-made gloves. They make 200 to 400kg of animal food every hour, it is perfect for farms with 50 to 300 cows. Here’s the simple truth: Small family farms use 200kg/hour to feed 100 animals daily.

Large farms need 400kg/h but they do not need to buy a new machine. The secret? A special motor that uses less power than old models. It can save $100 monthly on electric bills.

When rains ruin grass, the machine makes 380kg/hour. In dry months, it makes at 210kg/hour. The tough metal parts with high quality-certified can handle these changes easily. The feed pellet machine can work for over 8 years with basic care.

VTKLP-210: Understanding Its Key Features

The VTKLP-210 feed pellet making machine can work well with strong structure and easy operation. It can turn raw materials into same-size feed pellets quickly with its advanced technology. It can handle heavy daily work without breaking down. Farmers and factory workers like how it makes less waste when creating animal food.

Big and small farms can operatie easily and effectively with its simple structure and operation. The advanced design helps farmers in Colombia to save raw materials while keeping feed quality high every time. The animal feed pellet machine also strictly follows agricultural machinery standards, so a lot of people trust it can work year after year.

Buying the equipment for commercial business, it can reduce cost through energy savings. For small farm or home use, the feed pelletizing mill can work great in a safe, easy and cleaner way. It is very popular in animal feed production for different farm size with this dual benefit. The steel parts can resist rust and wear, it will have fewer repairs over time.

The mixing system of the machine can make feed pellets with better nutrition balance compared to regular machines. This can help animals to grow much healthier while reducing food waste. It can keep steady performance even though long working time whether you make chicken feed or cattle feed.

After-Sale Services and Support

When our poultry feed machines arrive like the VTKLP-210 in Buenaventura, our certified engineers spring into action. They will help you to set up your equipment within 48 hours, and teach your team to run it smoothly.

We have spare parts ready in Colombia, so if any issues pop up, you can fix it fast usually within 2-3 working days. Our 24/7 support team (with 10+ years of feed machine know-how) speaks both Spanish and English. They’ve handled over 300 maintenance cases in South America alone.

Whether it’s a sensor check or production tweak, we’ve got solutions that match ISO 9001 quality standards. For long-term success, we create custom care plans.

What’s Next for Feed Production in Colombia?

Smarter Feed Pellet Machine Work Better

Our feed making machines use advanced smart technology like computer control. The pellet making machine can handle different crops like corn, soybean, or even cassava. They can make 15% more feed per hour with less power. Over 50 farms in Colombia are using these energy-saving machines.

Earth-Friendly Feed Making

More mills now use natural glue instead of chemicals to bind feed. They recycle 9 out of 10 water buckets used in production, meeting strict global eco-rules called ISO 14001. Farmers report crops grow stronger with feed made from sustainable palm kernels, which use 30% less water than old ways.

Special Feed for Every Animal

The feed for diary cattle is diferent from chickens. Feed pellet making machine can add extra rich protein or calcium into feed pellets. A Medellín chicken farm in Colombia saw 18% more eggs after using calcium-rich feed.

World Teams Share Knowledge

Colombian engineers recently learned how to trick moisture from German experts. They help farmers to keep feed fresh 40% longer expecially in wet weather. Working with Brazilian scientists, they’re making drought-proof feed with local plants that grow in dry seasons.

Feed Pellet Making Machine Price in Colombia

Understanding Price Ranges

In Colombia, animal feed pellet machine price range from $500 to $30,000. Smaller units for family use or samll farms often cost less, while the price for large feed factory or big farm may be very higher with heavy duty and high quality. You should always check both buying costs and yearly upkeep, because a $5,000 machine might need $800/year in maintenance.

Size Matters for Your Farm

A chicken feed maker which can make feed of 200kg/hour costs about $3,000. It is good for 500 chickens. Larger models making 2 tons/hour (enough for 5,000 birds) cost around $18,000. Most Colombian farm owners choose mid-sized machines that handle 500kg/hour.

Local vs Imported Machines

You should check the quality and warranty terms when the feed pellet machine price in Colombia local is less 20%. High quality feed pellet machine might cost $25,000 plus shipping from importing, but the machines have high quality and better warranty terms.

Service Plans Protect Your Investment

The machines cost more 15%, but the sellers may supply 2-3 years service, they can fix breakdowns in 48-72 hours. One of our customers saved $4,200 last year, they use preventive maintenance plans that spot worn parts before they fail.

Complete Systems Work Better

A full setup with mixer, grinder, and bagger costs $45,000-$60,000 – cheaper than buying each piece separately. Many Bogotá farms save $8,000-$12,000 buying package deals that include training videos in Spanish.

Smart Buying Tips

Check exchange rates – when the peso grows strong, imported machines get cheaper. Local farm co-ops often get group discounts of 10%-15% on multiple orders.